The simple answer is definitely – yes! Hand-drawn and coloured sketches of bespoke furniture proposals are lovely to look at and some seem good enough to frame and hang on a wall. But for practicality, a 3D computer model wins hands down.

When to sketch and when to model

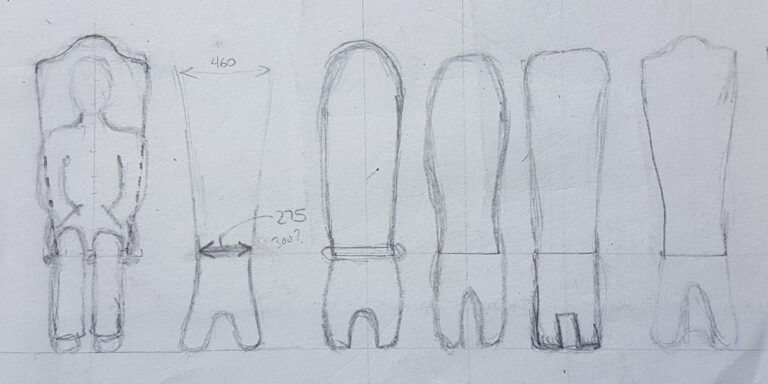

There is definitely still a place for sketching in the world of furniture design. For example, conceptual sketches such as these rough sketches of alternative back designs for my Chief’s Chair. It is generally simpler and quicker (and possibly more relaxing) to roughly sketch out ideas and filter the wheat from the chaff that way.

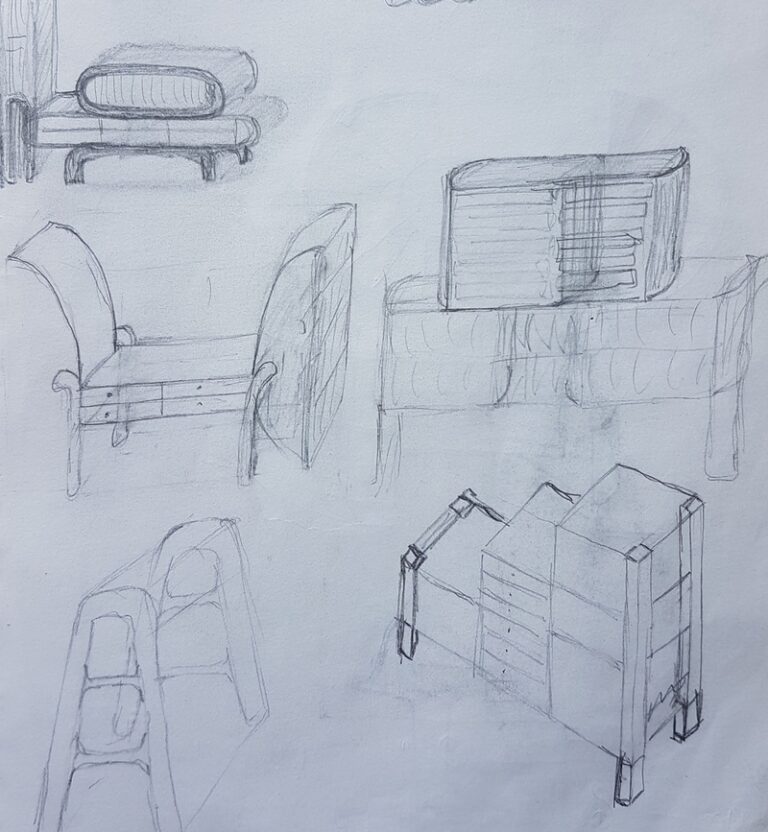

Then there are sketches that are made to capture those ideas that fly through a designer’s head, and which may one day be useful, but aren’t yet complete, fully formed or useful right now.

But for presenting a design or design alternatives to a client, a 3D model has to be the way to go.

3D computer models versus physical models

Just to be clear, the models under discussion here are 3D computer generated models, or digital models, not physical models.

It is rarely economic to produce a physical model simply to demonstrate how an item will look. There are times when a complex design or unusual structural layout will drive the need for a mock up that proves the concept, and in turn gives a representation of the end product. However, this scenario is unusual and for most situations a computer generated 3D model provides the client with the best appreciation of how the finished article will look.

In addition, as initial designs often need further tweaks or adjustments during a process of engagement with the client, these adjustments are most easily achieved with a computer generated 3D model rather than a physical model.

Benefits of computer generated 3D models

Using 3D modelling to prepare bespoke furniture design proposals brings many benefits, both for the prospective client and for the designer/maker:

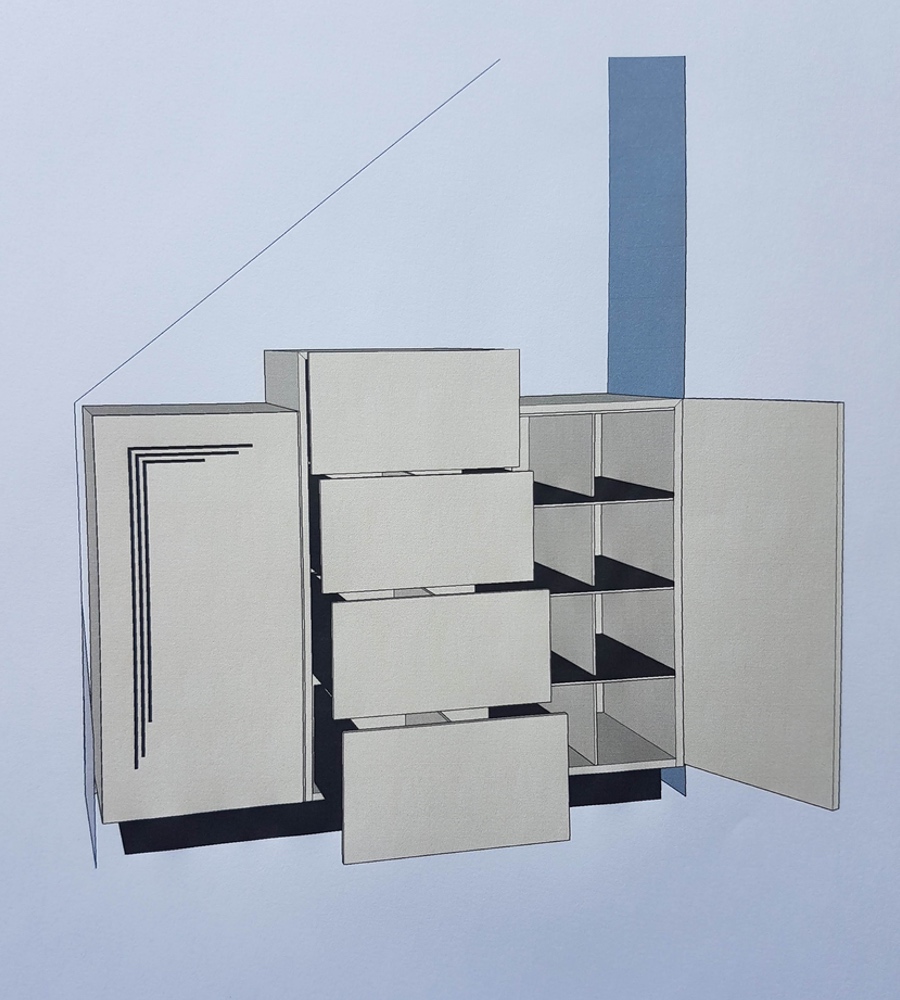

- Once a 3D model has been produced, the proposed design can be easily viewed from any angle. This means that it is easy to provide the client with an idea of what the final piece will look like from any viewpoint.

- During the design process, there will inevitably be design changes, as discussion progresses. Once a 3D model has been produced, although it still takes time to alter the initial design, it will be a simpler and quicker process when compared to making several new drawings each time the design is changed.

- With a 3D model, drawers and doors can be shown open or closed very easily and the interior of a piece can be displayed without further drawing work being necessary.

- Given the unique nature of a bespoke piece of furniture, there is often nothing of a similar nature to be viewed as an example, so a model provides the best way of visualising it.

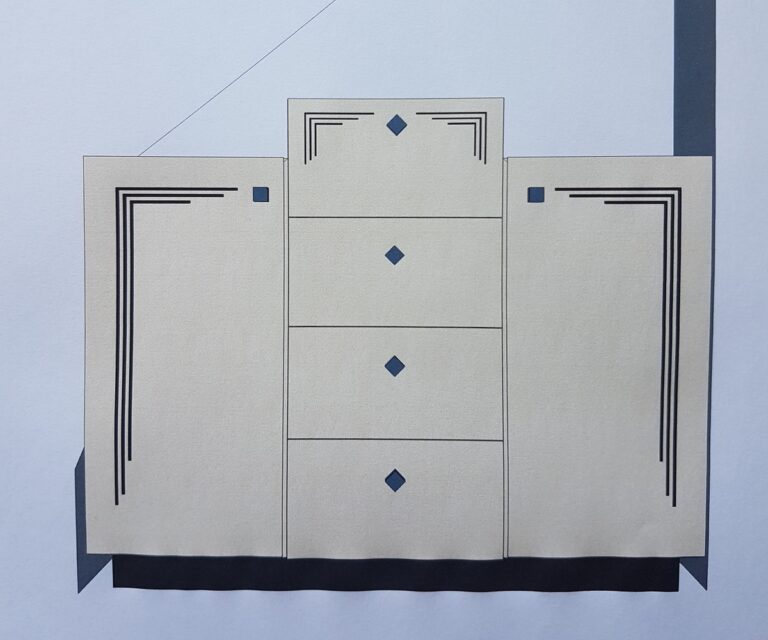

- The surroundings in which the piece of furniture will be placed, can be added to the model. Even if this is shown in a fairly crude way, as in the Walnut Hall Cabinet example below, it makes it easier for the client to see the piece in-situ and get a good appreciation of how it will fit into their existing space.

- For the designer, once a 3D model has been completed, discussed, tweaked and finally agreed with a client, it can be used to prepare the dimensioned drawings needed to make the piece.

- The maker is more easily able to see how the designer intended for the piece to be constructed, by looking into the 3D model.

So my advice would be that 3D computer modelling in bespoke furniture design is a must!